Opis

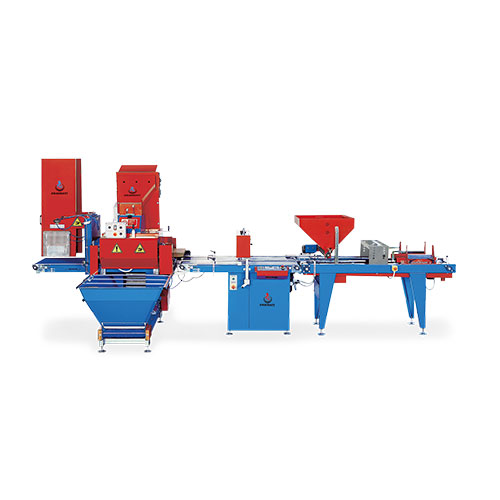

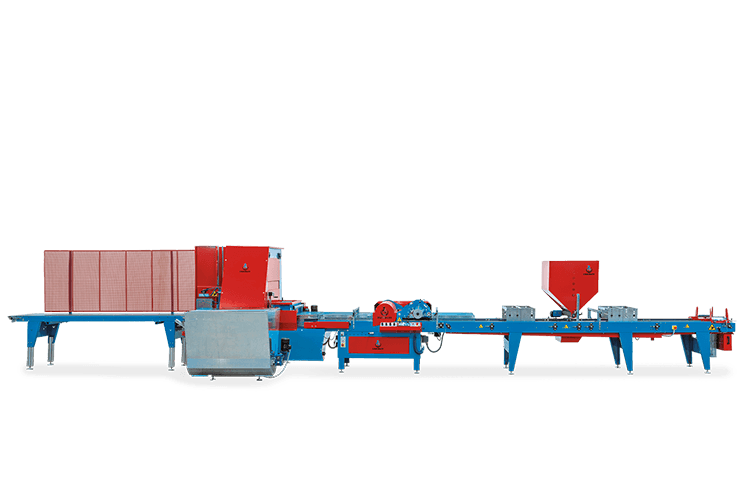

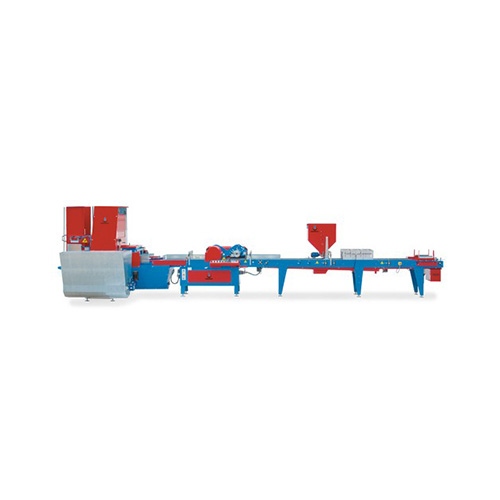

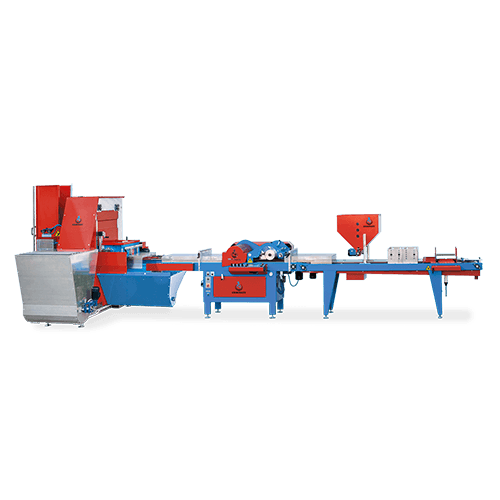

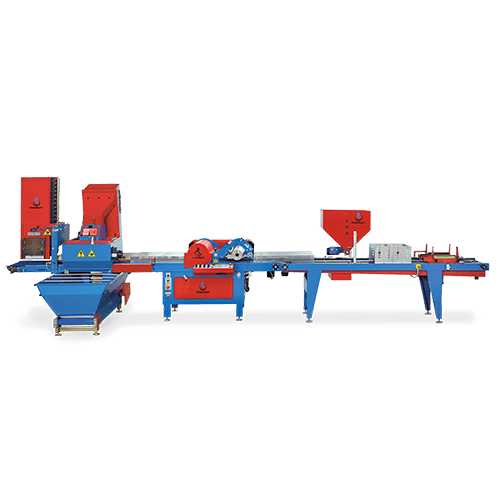

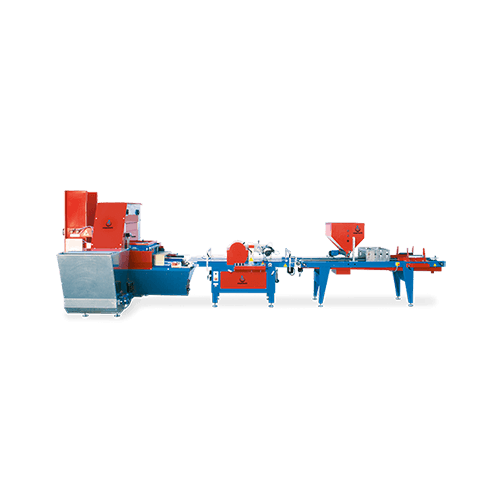

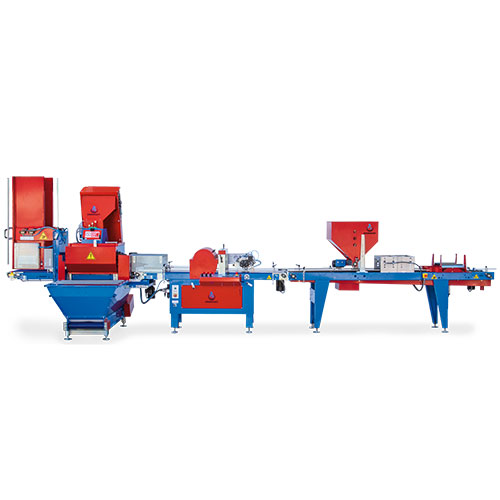

The compact Kappa65C row seeding line can reach a capacity of up to 2,400 rows/hour.

The multiplats are arranged on a filling conveyor belt one after the other, thus ensuring maximum even filling in all their cells, including those located along the edges of the multiplats. The filling density is adjustable with a single handle, allowing it to vary from low to medium to high density. Cleaning brushes thoroughly clean multiplates from excess substrate.

The automatic in-row seeding unit is electronically controlled, allowing accurate spot seeding of one or more small as well as large seeds in the same cell.

Different types of nozzles are available as add-ons to satisfy all expectations (silicone, multi-seed seeding, etc.).

The control panel for data display, programming, production and diagnostics can store up to 99 seeding programs.

The pneumatic vibrator of the seed container improves the operation of the device and, consequently, it functions efficiently even when the amount of seeds is small.

A sprinkling unit for vermiculite or other granules ensures even coverage, allows you to choose its width, as well as the amount of product distributed to prevent any loss.

Every component of the machine is designed and manufactured to improve the work of operators, minimize machine handling and increase the speed of seed changes.

Capacity / hour. (min-max): 2400 mltpl./hour (KAPPA65C), 2400 mltpl./hour (KAPPA65C E)

Dimensions of multiples (max): 750×400 mm (KAPPA65C), 750×500 mm (KAPPA65C E).

Weight: 980 kg (KAPPA65C, KAPPA65C E)

Vacuum pump: System Venturi model (KAPPA65C, KAPPA65C E).

Air consumption (max): 290 l / min (KAPPA65C, KAPPA65C E)

Water consumption up to 2 atm (max): 20 l / min (KAPPA65C, KAPPA65C E)

Appliance power: 4.5 kW (KAPPA65C, KAPPA65C E)