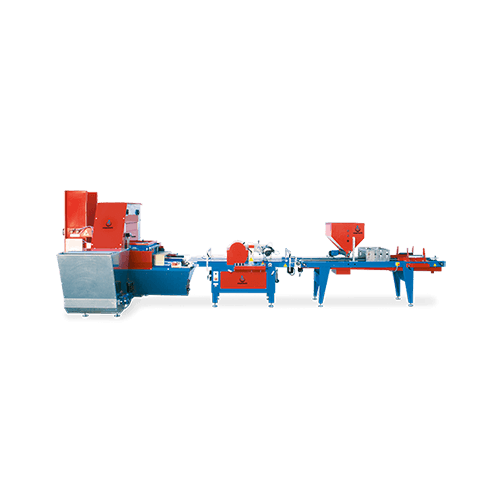

Opis

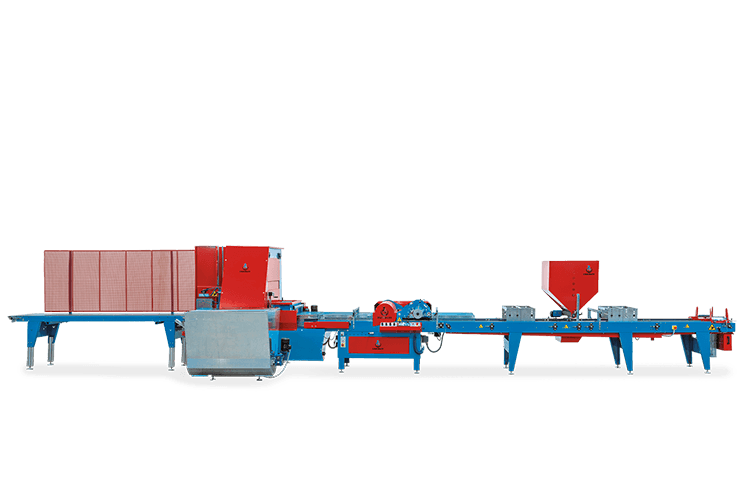

Sigma80 drum seeding line can achieve high productivity due to the transverse location of the multiplatforms

relative to the conveyor belt on which they are later filled, thus minimizing machine handling. Better substrate clearance is provided by moving the multiplats forward of each other, but they remain disconnected.

The multiplats are stacked on a conveyor belt one behind the other, thus ensuring maximum even filling in all their cells, including those located along the edges of the multiplats. The filling density is adjustable with a single handle, allowing it to vary from low to medium to high density. Cleaning brushes thoroughly clean the multiplates of excess substrate, which is completely recovered without any loss of substrate.

The hole-making drum guarantees the central location of the cell cavity and its perfectly round shape.

The technical solutions of the presented seeding unit allow spot seeding of both small and large seeds. A second seeding drum can be added to apply multi-seed seeding or to dispense granular fertilizer.

Changing the type of seeds and/or multiplats is done very quickly, thanks to the efficient adjustment and changing of drums without the need for any tool.

A sprinkling unit for vermiculite or other granules ensures even coverage, allows you to choose its width, as well as the amount of product distributed to prevent any loss.

Every component of the machine is designed and manufactured to improve the work of operators, minimize machine handling and increase the speed of seed changes.

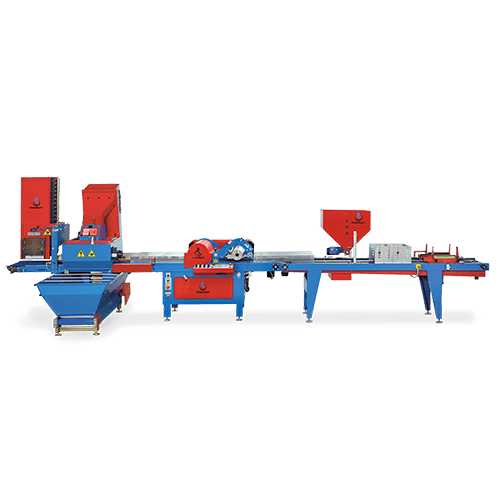

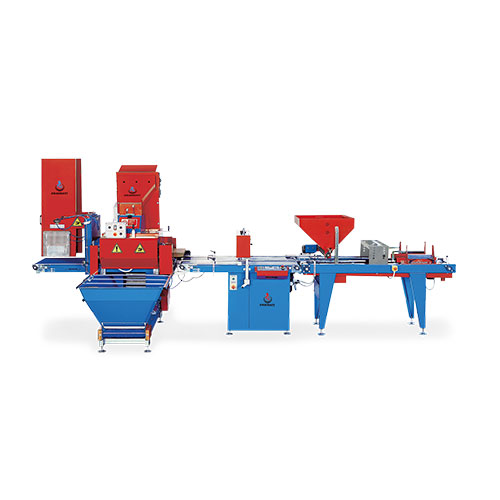

Capacity / hour. (min-max): 200-1800 mltpl. / hr.

Multiples dimensions (max): 600×400 mm

Weight: 2470 kg

Vacuum pump: model PVA 1800

Air consumption (max): 300 l / min

Water consumption up to 2 atm (max): 50 l / min

Unit power: 12 kW