Opis

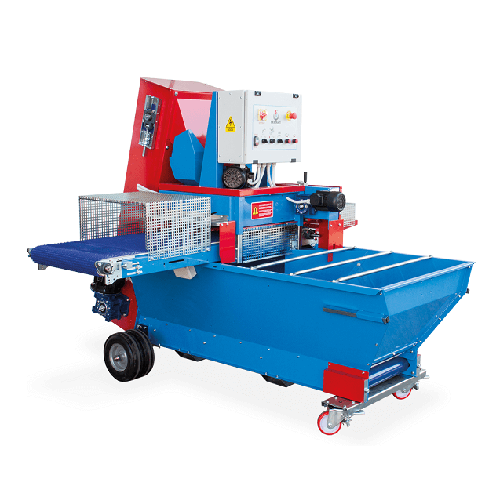

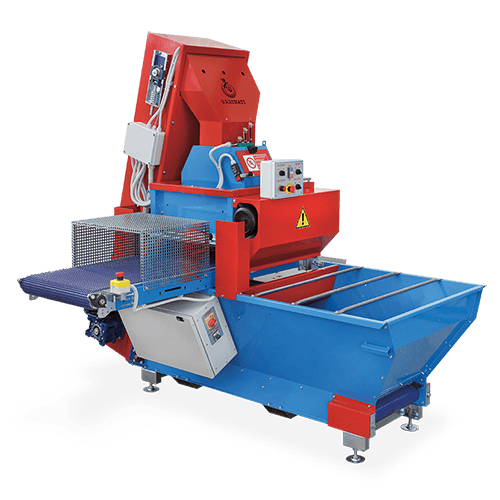

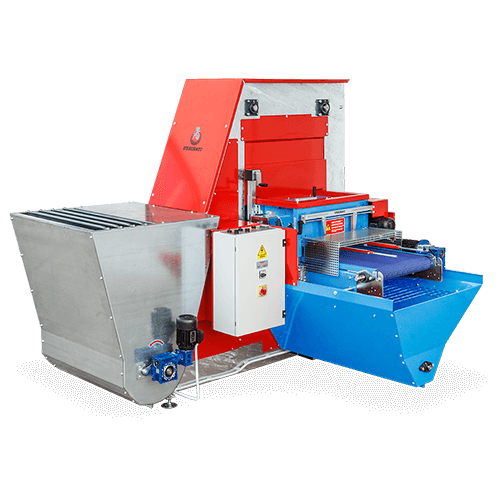

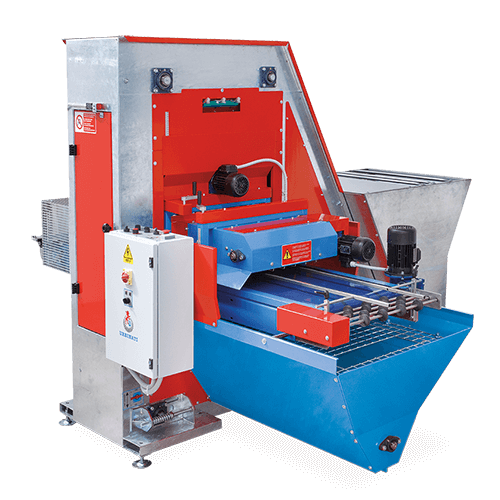

The Urbinati RE14 multiplier filler is the smallest available filler offered by Urbinati. However, this does not mean that it is the weakest model. On the contrary, it is a proven and effective unit that will work well on small farms but also on larger ones, where it can be part of small production lines. The operation of this unit is fully automatic, and with the ability to adjust the among others. the degree of compaction of the substrate or the speed of work, provides great and reproducible results. This filler consists of three main modules – the substrate hopper, the elevator and the backfilling unit. The substrate reservoir is a tank with a capacity of about 700 l. At its bottom is a belt that transports the substrate in the hopper toward the elevator. The speed of the conveyor belt is mechanically adjustable, so we can set the optimal one that will ensure continuous availability of the substrate in the elevator. The elevator is used to transfer the substrate/substrate from the hopper to the backfill unit. For this purpose, it has been equipped with specially formed blades made of high-quality galvanized steel, which ensures trouble-free operation for a long time.

The chains to which the shovels are attached have adjustable tension and a safety device that protects the elevator from mechanical damage. The substrate transported by the elevator is dumped into a specially shaped hopper, where it enters a 3-armed rotor that, rotating, fills the multiplates passing under it. The speed of the rotor can be continuously adjusted by means of an inverter. Such a solution ensures that an equal degree of filling and compaction is achieved in each filled multiplate, which is extremely important in crop production. Multiplates are transported under the rotor using a conveyor belt. In the standard configuration, both input and output multiples must be given and received manually. It is possible to equip the filler with optional accessories, such as an automatic multiplier feeder that will separate and feed individual multiplates from the stack. The conveyor belt has also been equipped with an electronic speed control, so that the filling level of the multiplats can be further adjusted. If you are using high multiplates, with a specific shape, or those that require strong compaction, you can equip the machine with a special frequency-controlled vibrating unit mounted under the belt, which further compacts the backfill. At the output, the machine can also be equipped, for example, with special rollers that facilitate the recovery of excess used substrate, or a short acceleration conveyor that will pick up the filled multiplat and feed it to the next unit in the line.

The machine is sturdy, simple to use and easy to maintain. In particular, it is recommended wherever it is necessary to change the substrate quickly while being able to completely and quickly clean up the residue of the previous substrate. Emptying the hopper and completely cleaning all modules is very easy and fast. The same applies to the adjustment when changing the type of multiplier to be filled, which is done using side guides and a central height adjustment, and the whole process takes literally a few moments. For these reasons, this filler will work great as a stand-alone unit but also as a unit that is part of a production line. Thanks to its small size, it can easily fit into even cramped production halls, and can be easily transported to the storage area after finishing work. In conclusion, the Urbinati RE14 filler is a unit that will work well in many applications and will make the filling of multiplats a pleasant, efficient and repeatable job, which in turn will translate into the quality of the plants grown.