Opis

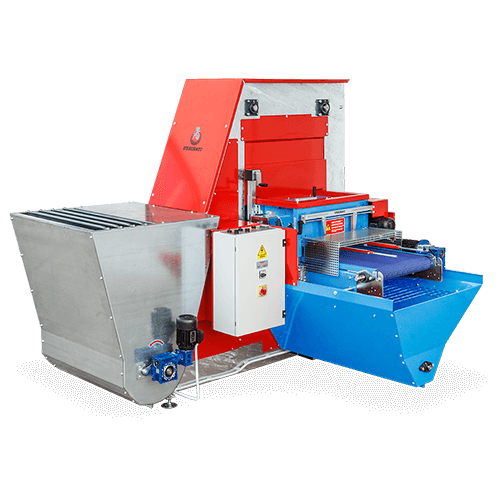

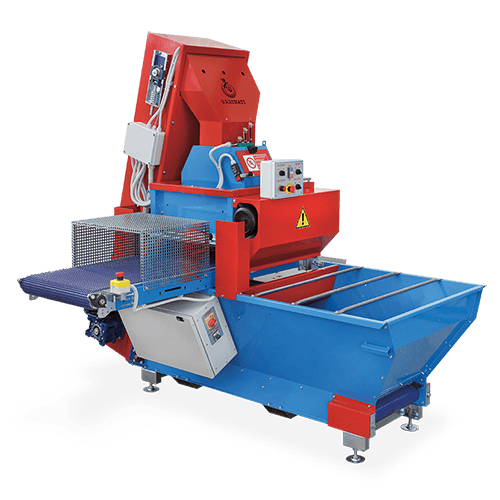

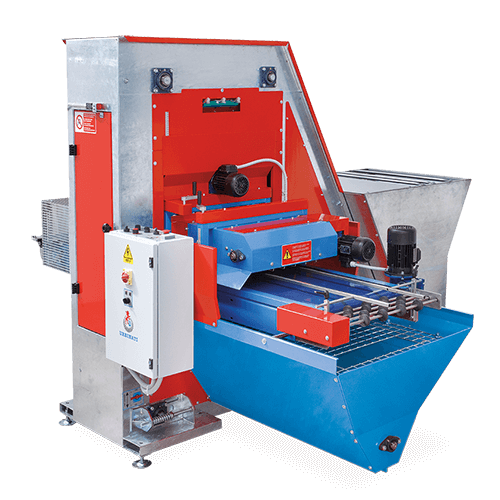

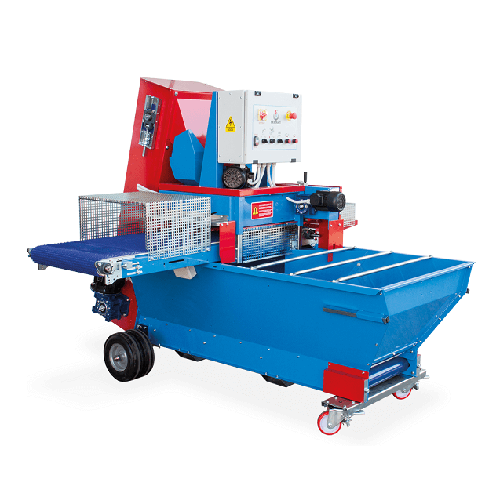

The RN12 multiplate filler is one of the largest and most technically advanced devices designed for automatic filling of various types of multiplates. It is a device that can work as a stand-alone unit, but its main purpose, due to the sensational performance it offers, is the construction of high-performance production lines designed both for sowing seeds and for filling multiplats used in classic seedling production, and ending with transplanting lines. Due to its technical capabilities and performance, it is one of the best and most popular models in the range of fillers offered by Urbinati. Like other models, this filler consists of 3 basic modules – the substrate tray, the elevator and the backfilling module. There would be nothing special about this if it weren’t for the fact that each of these modules incorporates the best available technology. The unit features a 600-liter substrate storage tank, which can be optionally expanded to as much as 900 liters. Such an enlargement will provide the adequate substrate buffer necessary for continuous operation even with high-capacity multiples. The most common, however, is a standard substrate storage tank combined with an efficient substrate source in the form of various buffer units and other available solutions. The hopper has been equipped with special shovels that, as they move, loosen the substrate inside it, making it constantly accessible. Another important aspect is that the substrate from the hopper is taken directly by the elevator shovels, so the substrate is delivered to the hopper continuously. In addition, the unit is equipped with a specially designed return system for unused substrate using an auger that transports excess substrate directly under the elevator blades, giving the ability to use excess substrate continuously. The substrate is transported by means of an elevator, the construction of which is based on chains with attached special blades made of high-quality galvanized steel. Of course, it has been equipped with a special system that allows the chains to be tightened if necessary with a safety system to prevent breakage. The elevator can perfectly cope with different types of substrates, both light and heavier substrates, and this substrate does not affect its work. The substrate goes into a special hopper from where it goes to the mulitplat. This module, too, is equipped with a number of solutions to ensure that the filling process is of exceptional quality and repeatability. First of all, the hopper provides a kind of buffer for the substrate, and the amount of this substrate is regulated by electrodes that control its level. Thanks to the ability to adjust the position of the electrodes, we can get the optimal amount of substrate ready for use, and at the same time there is no risk of compaction, because when the preset amount of substrate in the hopper is reached, the system automatically stops the elevator. Filling the multiplats with substrate is carried out by a special rotor made of 4 horizontally arranged blades, which rotate to fill the cells of the multiplats with substrate. By adjusting the height of the rotor above the surface of the multiplat, we can adjust the degree of substrate compaction in the multiplat cells. ożaAdditionally, we can change the direction of rotation of the rotor, which also has a direct effect on compaction. In this quick and easy way, accessible from the machine operator’s position, we can quickly and easily change between light and heavy compaction of the ground. In the case of using high multiplats, especially those for sowing seeds of forest trees, in which individual cells have small diameters while reaching a high height of 18-20 cm, an additional vibrating unit is used, which is mounted under the conveyor belt that transports multiplats under the chute hopper. The unit is equipped with adjustable vibration frequency, which further ensures that optimal filling results and the same quality can be achieved in all filled multiples. The filled multiplat is transported toward the next unit passing under a cleaning system consisting of a special height-adjustable brush, and the excess substrate is dumped into the backfill and reused.

The filler is equipped with an infinitely variable speed control, so the speed of operation can be adjusted as needed. In addition, the machine features an easy width adjustment system that makes it easy to position the multiplats centrally under the substrate backfill and allows the machine to be adjusted smoothly and quickly to another type of multiplat. This device can be equipped with a number of additional options, including. various types of automatic multiplier feeders, which significantly improve the work and affect its efficiency.

The Urbinati RN12 filler is a robust and large machine that, despite its advanced technology, is very easy to operate, adjust and service. It has been equipped with a number of innovative technical solutions, thanks to which it is possible to fill most of the multiplats available on the market with the expected degree of compaction and homogeneity of filled multiplats, which translates into better results in plant cultivation. It is recommended wherever a filler with very high capacity and performance is needed while maintaining the highest quality of filling. This device is especially recommended for creating seeding lines in nursery farms engaged in the production of forest tree seedlings. It works well in such use and enjoys a great reputation.